How Chiller Systems Works?

In this Article we are going to discuss about BMS systems part 2 , for Complete working principle of Chiller system.

Chiller System

Centralized air conditioning system used for large cooling capacity usually for commercial purpose.

Its consist of three main cycles

- Refrigerant cycle

- Chilled water cycle

- Condenser water cycle

- The component that are involved in refrigerant cycle are (Compressor , Condenser , Filter Driver , Expansion valve and Evaporator).

- For Chiller water system that are involved in air handling unit and water pump,

- Condenser water cycle the component that are needed to process are cooling tower and water pump.

|

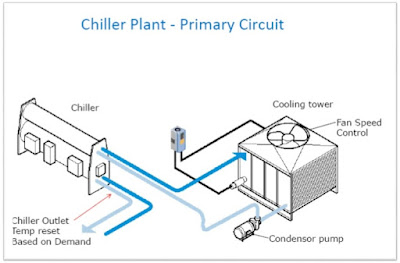

| Primary Circuit |

|

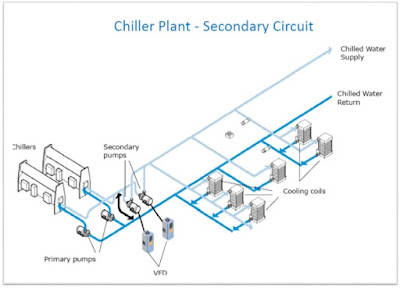

| Secondary Circuit |

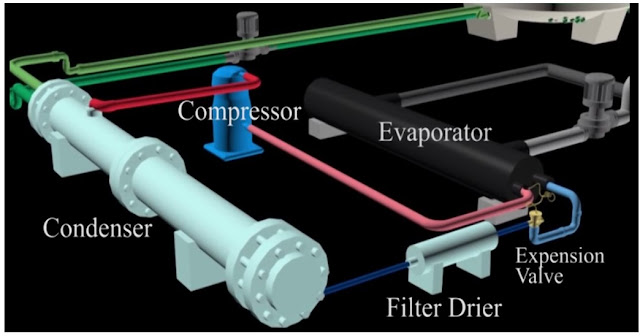

Refrigerant cycle

- Refrigerant cycle consists four basic components , which are (Compressor , Condenser , Expansion device , and Evaporator and additional component called Filter driver )also include in the system.

Compressor

- Compressor works to increase the pressure of the refrigerant and addition it also increase the temperature of the refrigerant higher then temperature of condenser water so that the heat transfer in the condenser.

- The refrigerant ten-tees compressor with low pressure gas and out with high pressure gas condition, type of compressor used is scrolmatic type , Scroll compressor works based on gas at low pressure on the temperature into the suction line and go into the compressor.

- The low pressure in the temperature gas is pressurized by the scroll compressor at high pressure and temperature gas , the high pressure in the temperature gas’s then through the discharge line and then go into condenser.

Condenser:

- The refrigerant in high pressure gas will be entered the condenser at the temperature higher then the temperature of condenser water in condenser.

- The heat will be eliminated through the condenser water from the cooling tower through the proceed of conversation and conduction.

- After the heat is removed the refrigerant in the high pressure gas conductance in the high pressure liquid when out from the condenser.

- Condenser is most commonly used shell and tube type water is flowing through the tube refrigerant liquid from fluted in the shell.

Filter driver:

- Before the refrigerant float in the next main component it will be passes through an additional component called dryer.

- Dryer act as a duct filter and observe if there is moisture in the refrigerant this will shows that refrigerant is clean and dry before entering in the expansion valve.

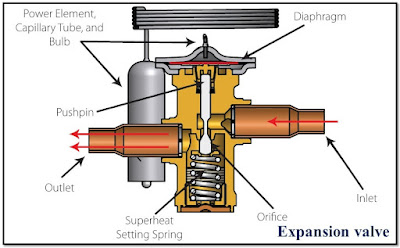

Expansion valve:

- Expansion valve service to reduce the pressure in control flow of refrigerant going into the evaporator, when the pressure of refrigerant is decline tactically the temperature air will dropped dramatically which is lower than chiller water temperature.

- In a centralized system expansion device to the xv thermal expansion valued type is used, it work according to the temperature of the refrigerant which comes out from the evaporator sensing bulb placed on the flow of the evaporator works to detects temperature of the refrigerant in sense the signal to TXV needle valve in the TXV will control the flow of refrigerant based on the transmitted signal.

Evaporator:

- The refrigerant in the low pressure liquid from coming out from in the expansion valve will flow into the evaporator at low temperature.

- In evaporator the heat from the chilled water which comes out from the air handling unit to will observed by the refrigerant due to the temperature different procure.

- when the liquid refrigerant which the low temperature and pressure observe heat from the chilled water the refrigerant will evaporator at low pressure gas.

- The evaporator most commonly is used shell and tube type where the refrigerant flow in the tube and the water floated the Shell.

- The evaporator slighted with in the installation reduce heat transfer , the refrigerant in the low pressure gas will returned the compressor and continuous to the next cycle.

Chiller water cycle:

- Chilled water cycle consist of two basic component which are air handling unit and water pump.

Air handling units:

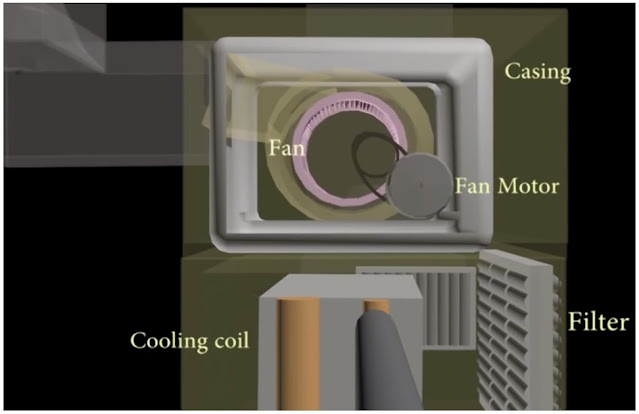

- Air handling unit is the placed where clod air is produced before it can be distrusted it consist of several key components such as ( Cooling coil , Fan , Fan motor , Belting , Filter and the Casing ).

- Chilled water produce in the evaporator flow into the air handling units through the pipe line which is marked with dark blue color , this chilled water is knows as chilled water supply in an air handling units.

- Chilled water will pass through the cooling coil , In the cooling coil the hot air will goes through the cooling coil and switched cold air due to the heat transfer to the chilled water, cooling coil are commonly used in system valve tube and fin , after observing the heat from the hot air the chilled water will be knows as chilled water return.

- Normally chilled water is turned with colour light blue , chilled water return will return back to the chiller to transfer the heat observe the refrigerant in the evaporator.

Water pump:

- This cycle will continue as long as the pump is functioning well.

- The pump used in the system is centrifugal type, the centrifugal pump works based on centrifugal force produce by the rotating impeller in the pump casing for air flow system it is operating using impeller.

- Auxiliary fan which to create the air cycle from the room and mixed with the fresh air from the outside through the air handling unit and return back to the room.

- Type of fan used is centrifugal fan and power by a motor connected through the belting.

- The air flow through the channel is called ducting , there are two types of ducting are supply air duct , and return air duct.

- The air duct are coated with the insulating material consisting of fibre glass rapping with aluminium foil, it reduce heat transfer from the environment to the air duct.

- Air return to the air handling unit will pass through the filter before passing through the cooling coil and return back to the room this twin show that the air return into the room when clean condition.

Condenser water cycle:

- Condenser water cycle is consist of two basic component which are cooling tower and water pump.

Cooling tower:

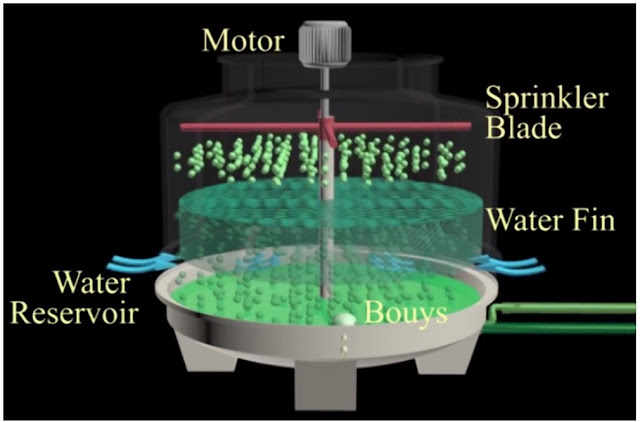

- Cooling tower service to the cool on the temperature condenser of water that will be used to observe the heat in the refrigerant Condenser , it consist of several components which are (Motor , Sprinkler blade , Water fin , Water reservoir , bouys , and Makeup water tank).

- Heating from the condenser in chiller , condenser water flow to the cooling tower with the help of the centrifugal pumps.

- This chilled water is called condenser water return.

- This condenser water will pass through the rotating sprinkler blade on cooling towers. This rotating blade using pressure generator by the condenser water it self.

- Water will goes down through the fin and reduce the speed of water will going down.

- This can delay time in the heat can be observe more effectively by the surrounding air at passing through the fins , air through the fins is fast by a rotating fan on the sprinkler blade rotate by the motor.

- This fan rotates with it cause supports this will close the air to move from the bottom to top of the cooling tower where if opposite to the flow of the condenser water.

- Condenser water which are eliminate the heat by the surrendering air will accumulate in the basin under the cooling tower.

- Condenser water that flowing out from cooling tower to the chiller is called condenser water supply.

- This condenser water will flow back to the chiller to continuous heat observing work from the refrigerant the bouy system at the water base nets connected to the makeup water tank.

- It works for adding water when the water level in the base is decrease its sertan level due to evaporation. This condensing water cycle coil continuous a longest centrifugal pump is good working condition.

Video Link :

We hope this Article will helpful to you , Thank you for visit our Blog

Thanks for sharing this awesome knowledge about chilled water system. We BSTC tech also provide services related to havc duct and chilled water system. Contact us now to know more.

ReplyDeleteHAVC Duct And Chilled Water System