Honeywell NX VFD drive Fault code

In this Article we are going to discuss about Honeywell NX VFD drive Fault code , Cause , and Remedy. The fault coding and trip logic are similar in all Honeywell NX inverters. This fault code , causes , and remedy are applies for both NXS and NXL HVAC.

Fault Code : 1

Overcurrent

Possible

Cause :

- Frequency converter has detected too high a current (greater than 4 * In) in the motor cable:

- Sudden heavy load increase.

- Short circuit in motor cables.

- Unsuitable motor.

Remedy:

- Check loading.

- Check cables.

- Check motor size.

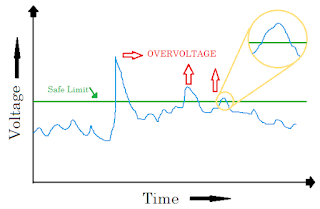

Fault Code : 2 Overvoltage

Possible Cause : The DC-link voltage has exceeded the limits defined in

- Too short a deceleration time.

- High over voltage spikes in utility.

Remedy:

Increase

deceleration time.

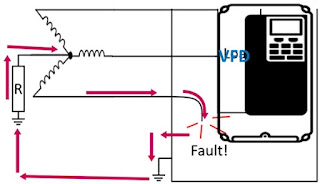

Fault Code : 3 Earth

fault

Possible Cause :

- Current measurement has detected that the sum of motor phase current is not zero.

- Insulation failure in cables or motor.

Remedy:

Check

motor cables and motor.

Fault Code : 5 Charging switch

Possible

Cause :

The charging switch is open when the Start command has been given.

- Faulty operation.

- Component failure.

Remedy:

- Reset the fault and restart.

- Should the fault recur, contact the technical support.

Fault Code : 7 Saturation Trip

Possible

Cause : Various causes, e.g. faulty component.

Remedy:

- Cannot be reset from the keypad.

- Switch off power.

- Do not connect power.

- Contact Honeywell.

- If this fault appears simultaneously with

Fault 1, check motor cables and motor.

Fault Code : 8 System

fault

- Component failure.

- Faulty operation.

Remedy:

Reset

the fault and restart. Should the fault recur, contact the technical support.

Fault Code : 9 Under

voltage

Possible Cause : DC-link voltage is under the voltage limits defined in:

- Most probable cause.

- Too low a supply voltage.

- Frequency converter internal fault.

Remedy:

- In case of temporary supply voltage break, reset the fault and restart the frequency converter.

- Check the supply voltage.

- If it is adequate, an internal failure has occurred.

- Contact the technical support.

Fault Code : 10 Input line Supervision

Possible

Cause : Input line phase is missing.

Remedy: Check supply voltage and cable.

Fault Code : 11 Output Phase Supervision

Possible

Cause : Current measurement has detected that there is no

current in one motor phase.

Remedy:

Check

motor cables and motor.

Fault Code: 13 Inverter under Temperature

Possible Cause: Heat sink temperature is under – 10 °C.

Remedy:

Check

that the inverter is operated under specified conditions.

Fault Code : 14 Inverter over Temperature

Possible Cause :

- Heat sink temperature is over 90 °C.

- Over temperature warning is issued when the heat sink temperature exceeds 85 °C.

Remedy:

- Check the correct amount and flow of cooling air.

- Check the heatsink for dust.

- Check the ambient temperature.

- Make sure that the switching frequency is not too high in relation to ambient temperature and motor load.

Fault Code : 15 Motor Stalled

Possible Cause : Motor stall protection has tripped.

Remedy:

- Check motor.

- Check that pump or fan is not blocked.

Fault Code : 16 Motor over Temperature

Possible Cause :

- Motor overheating has been detected by frequency converter motor temperature model.

- Motor is overloaded.

Remedy:

- Decrease the motor load.

- If no motor overload exists, check the temperature model parameters.

Fault Code : 17 Motor Under Load

Possible Cause : Motor under load protection has tripped.

Remedy:

- FAN: check that belt is not broken.

- PUMP: check that pump is not dry.

Fault Code : 22 EEPROM Checksum Fault

Possible Cause : Parameter save fault:

- Faulty operation.

- Component failure.

Remedy:

Contact

the technical support.

Fault Code : 24 Counter

fault

Possible

Cause : Values displayed on counters are incorrect.

Remedy:

Contact

the technical support.

Fault Code : 25 Microprocessor Watchdog Fault

Possible Cause :

- Faulty operation.

- Component failure.

Remedy:

- Reset the fault and restart.

- Should the fault recur, contact the technical support.

Fault Code : 29 Thermistor

fault

Possible

Cause : The Thermistor input has detected increase of the

motor temperature.

Remedy:

- Check motor cooling and loading.

- Check thermistor connection. (If thermistor input is not in use, it has to be short circuited.)

Fault Code : 32 Fan Cooling

Possible Cause : Cooling fan of the inverter does not start, when ON command is given.

Remedy:

Contact

the technical support.

Fault Code : 34 Internal Bus Communication

Possible

Cause : Ambient interference of defective hardware.

Remedy:

Should

the fault recur, contact the technical support.

Fault Code : 35 Application

fault

Possible

Cause : Selected application does not function.

Remedy:

Contact

the technical support.

Fault Code : 39 Device Removed

Possible Cause :

- Option board removed.

- Drive removed.

Remedy:

Reset

the VFD drive

Fault Code : 40 Device unknown

Possible

Cause : Unknown option board or drive.

Remedy:

Contact

the technical support.

Fault Code : 41 IGBT

Temperature

Possible

Cause : IGBT Inverter Bridge over temperature protection has

detected to high a motor current.

Remedy:

- Check loading.

- Check motor size.

Fault Code : 44 Device

change

Possible Cause :

- Option board changed.

- Option board has default settings.

Remedy:

Reset

the VFD drive

Fault Code : 45 Device

added

Possible

Cause : Option board added.

Remedy:

Reset

the VFD drive.

Fault Code : 50 Analogue

input line current less than 4 milliamps (selected signal range 4 to 20 milliamps)

Possible Cause :

- Current at the analogue input is less than 4 milliamps.

- Control cable is broken or loose.

- Signal source has failed.

Remedy:

Check

the current loop circuitry.

Fault Code : 51 External

fault

Possible Cause :

- Digital input fault.

- Digital input has been programmed as external fault input and this input is active.

Remedy:

- Check the programming and the device indicated by the external fault information.

- Check also the cabling of this device.

Fault Code : 52 Keypad Communication Fault

Possible Cause : The connection between the control keypad and the frequency converter is broken.

Remedy:

Check

keypad connection and possible keypad cable.

Fault Code : 53 Field bus Fault

Possible Cause : The data connection between the field bus Master and the field-bus board is broken.

Remedy:

- Check installation.

- If installation is correct, contact the technical support.

Fault Code : 54 Slot Fault

Possible

Cause : Defective option board or slot.

Remedy:

- Check board and slot.

- Contact the technical support.

Fault Code : 55 Actual

value supervision

Possible

Cause : Actual value has exceeded or fallen below the actual

value supervision limit.

Remedy:

Check

the process.

Will we hope this Article is useful to you , so let us know what you like and how we could do make better Article please leave your comments.Thank you for watching Visit our Blog , we will meet in an another good Article.

useful

ReplyDeleteinformative article...

ReplyDelete