Pressure sensors Installation Method

In This Sensor Installation Method Article Series , Today we are going to discuss about Pressure sensors Installation Method , Sensor's Installation Method Series Part-2

Pressure

General

- Pressure sensors are affected by orientation (see manufacturer's installation instructions).

|

| 2 |

|

| 1 |

- Pressure tubes must be provided with an isolatable T-fitting near the device head for test purposes.

|

| 3 |

- To prevent overload on one side when making adjustments, the connection must always be fitted with an isolating bypass.

|

| 4 |

- Where there is a risk of condensation, the differential pressure tube must be installed at a gradient of 1:30 and fitted with a drain mechanism.

- The drainage point must be lower than the device head and sensing point.

- Protect from frost and avoid U-shapes.

- Pressure tubes containing circulating air must not be introduced into the open air or routed through cold rooms or ducts.

- This prevents the risk of condensate freezing in the tubes (e.g. with pneumatic venting sensors).

- Mount on a vibration-free surface.

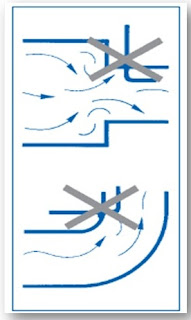

- The pressure-tapping point must not be located in turbulent air.

- Ensure sufficiently long settling zones upstream and downstream of the tapping point.

- A settling-zone consists of a straight section of pipe or duct, with no obstructions.

Pressure

Air

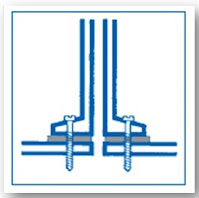

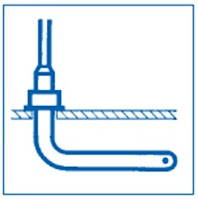

- The measuring tip is screwed or glued to the duct wall.

- Seal to protect from external air.

- Remove any swarf from the inside of the duct.

- Protruding fixing screws will impair correct measurement.

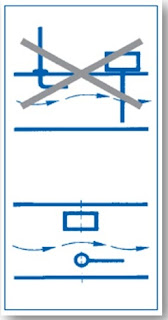

- Correct installation.

- Avoid using tips which protrude into the duct for static pressure measurements.

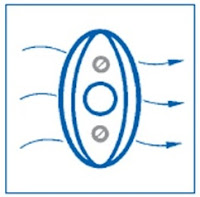

- Probes are used to measure static pressure in the duct.

- Must be installed parallel to the flow and either with the flow or against it.

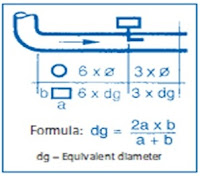

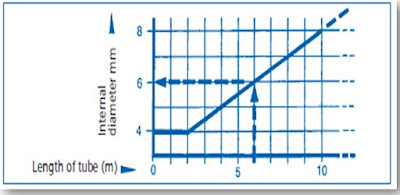

- Sizing the pressure tubes ('measuring tubes') for air and gases.

- Keep the tube as short as possible.

- An internal diameter of 4 mm is sufficient for pressure tubes of up to two meters in length.

- For longer pressure tubes, the internal diameter should be as indicated in the diagram.

- (Example: A pressure tube of 6 m requires an internal diameter of 6 mm.)

- Connect the sensor and measuring instrument to the same point.

- The tapping point must not be located where it will be affected by obstructions to the flow.

|

| 16 |

- Where more than one sensor is used, the sensors should be installed on the same plane in the flow, and not in a position where one device will obstruct the air flow to the other.

- dg = Equivalent diameter, Leave sufficient clearance downstream of any obstacles.

Pressure Room

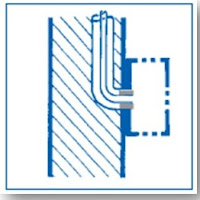

- The end of the pressure tube leading into the room should be protected by an air permeable cover.

- Seal gaps between cable/plastic tubing and conduit.

- Otherwise measurements will be falsified by incorrect circulation of the air.

Options:

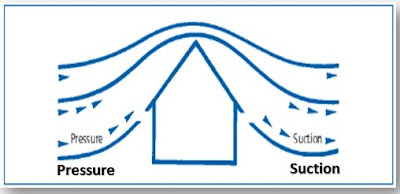

- Calculate average based on pressure measurements taken on several facades.

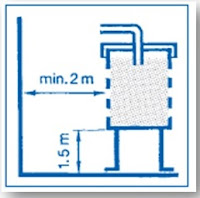

- Measure pressure in an open space (min 1.5 m above ground level).

- Multiple sensing point on flat roof.

Pressure

Outside air

- Measure the outdoor pressure in an area sheltered from wind. Individual facades are not suitable measurement locations, as the pressure varies according to the wind direction.

- The correct location for measurement is a place where the air can circulate freely, such as a flat roof.

Note : however, that the sensing point must be fitted with a wind

shield.

Pressure Liquids

Pressure tapping point:

- Sensing hole: diameter 5 mm, drilled and deburred.

- Smooth interior (no burrs).

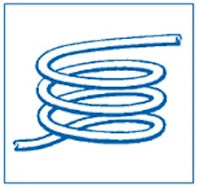

- Use a damping coil to avoid transferring vibrations.

- Bend a 1 m long copper pipe, 4.6 mm in diameter, into a spiral with loops with a diameter of 15 cm.

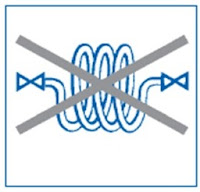

Wrong: Air bubbles and condensate remain trapped.

Wrong: Condensate cannot be drained.

Pressure measurement in conjunction with liquids :

- Do not measure at the top of the pipe (trapped air or air bubbles) or at the bottom (dirt).

- The correct location for a sensing point is at the side.

Condensing gases

- Measure at the top to prevent condensate from entering the pressure tube.

Installation in conjunction with liquids:

- Always install the pressure sensor in a location which is lower than the sensing point.

Installation in conjunction with vapours/gases

- Always install the pressure sensor in a location which is higher than the sensing point.

Well i hope this article was useful to you, If you need more informative Article please follow our Blogger. Thank you for Visit our Blog.Have a great day.

nice topic...

ReplyDelete