Flow Velocity Air and Liquid level Sensor Installation Method

In this Article we are going to discuss about Flow Velocity Air and Liquid level Sensor Installation Method , this is Sensor's Installation Methods video series part 3

General

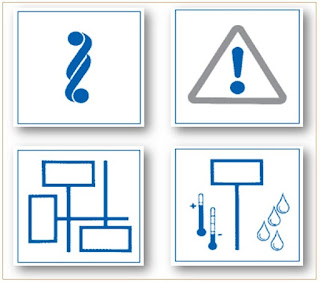

notes for all sensors

- Do not install sensors so that they protrude in any direction, and do not suspend them below the horizontal.

- Ensure that they are protected against damage and vandalism and will not cause injury.

- Be aware of the effects of orientation on the functioning of the sensor.

Always

determine the following before mounting:

- Minimum or maximum ambient Temperature

- Ambient humidity and exposure to spray water

- Exposure to vibration

- Explosion protection

- External influences

- Take account of the active and inactive sections of a sensor probe.

- A tight-sealing test-hole must be provided adjacent to every sensor.

- The cable should be installed with a drip loop to prevent water from entering the sensor housing.

- If the sensors are to be concealed (e.g. in false ceilings, shafts etc.), mark their locations visibly and record them in the site documentation.

- Always allow a sufficient length of spare cable so that the sensor can be removed at any time without disconnecting the wiring.

- When installing a sensor, avoid compressing the lagging.

- Use a graduated-diameter mounting flange to avoid compressing the lagging.

- If the mounting flange supplied does not have the appropriate graduations, use spacing bushes to avoid compressing the lagging.

- Fix a labeling plate in the direct vicinity of the sensor.

- This must include a plain text description and the reference number, which appears in the plant schematic. Do not attach the label to the device itself.

- The pressure-tapping point must not be located in turbulent air.

- Ensure sufficiently long settling-zones upstream and downstream of the tapping point.

- A settling-zone consists of a straight section of pipe or duct, with no obstructions.

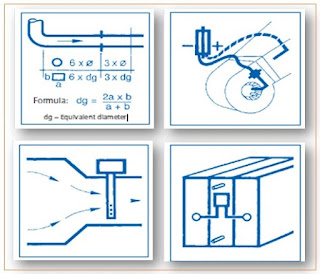

Fan-belt

monitoring :

The

differential pressure across the fan is only suitable for fan-belt monitoring.

- Negative connection (–) on suction side use copper tube.

- Positive connection (+) on discharge side: use Pitot tube.

Flow monitoring:

- Electro thermal flow detectors must be installed in a

zone with a high flow velocity, e.g. where pipes narrow.

- Do not monitor flow or differential pressure where flow resistance is variable, e.g. at filters, cooling coils, fans etc. Suitable locations: heating coils, silencers, baffles, attenuators.

Formula: dg =

Equivalent diameter

Flow monitoring Water :

- If differential pressure is used to monitor the flow, it is important to ensure that there are no stop valves or balancing valves between the sensing points.

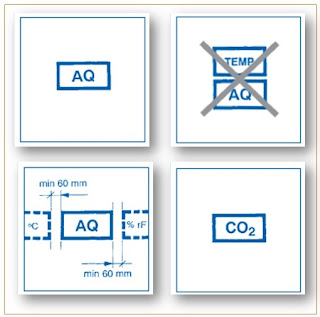

Air quality Room Sensors:

There are two types of air quality sensors:

Mixed gas or (VOC) sensors

- The accumulation of up to 24 different gases is measured in the ambient air (total concentration measured)

Selective gas sensors :

- These measure only one gas (e.g. CO2) in the ambient air (selective measurement).

- Do not locate temperature or humidity sensors above or below the AQ sensor.

- The heated sensor element produces significant intrinsic heat in the device.

- Owing to this characteristic, the room temperature or room humidity must not be measured in the immediate vicinity.

- Maintain a clearance of minimum 60 mm on each side of the AQ sensor.

- Selective gas sensors may require maintenance at regular intervals.

- Please consult the manufacturer’s instructions.

- The sensor must be installed in an accessible location.

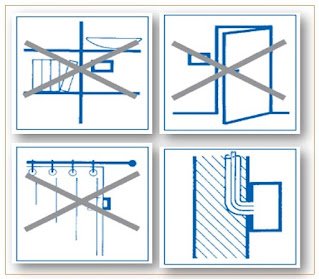

- Avoid recesses (e.g. shelving) and alcoves.

- Do not install directly adjacent to doors.

- Do not install behind curtains.

- Seal gaps between cable/plastic tubing and conduit.

- Otherwise measurements will be falsified by incorrect circulation of the air.

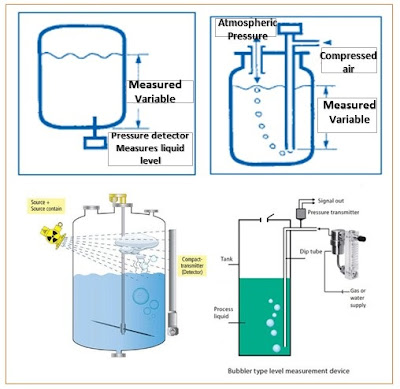

Liquid level Sensing:

A distinction is made between the following methods:

- Capacitive measuring probes

- Pressure/differential pressure (hydrostatic)

- Ultrasound

- Tank weighing systems

- Electromechanical sensing.

- The pressure is defined by the height of the liquid medium, measured from the sensor to the surface of the liquid.

- There are no critical factors to consider when installing the pressure sensor.

- The sensor material must be suitable for use with the liquid medium.

Bubble technique:

- The pressure measurement is determined by the height of the liquid above the bubble-tube outlet.

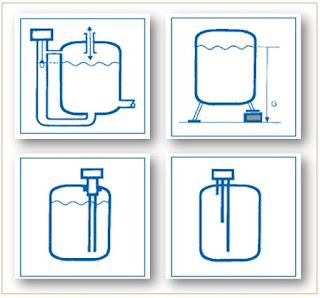

Floats:

- These are used in open and sealed systems.

- The device head must be installed above the maximum expected liquid level.

Tank weighing system :

- The measured result is determined by the tank content (mass weight).

- The sensor should be mounted in accordance with the manufacturer's instructions.

Capacitive measuring probes :

- These are used in open and sealed tanks.

Mounting:

- The distance from the next electrically

conductive component must be as specified by the manufacturer.

Conductance systems:

- These are used in open and sealed tanks.

- The measured result is determined by the length of the immersed electrodes.

Mounting:

- The distance from the next electrically conductive component must be as specified by the manufacturer.

- These are used in open and sealed tanks.

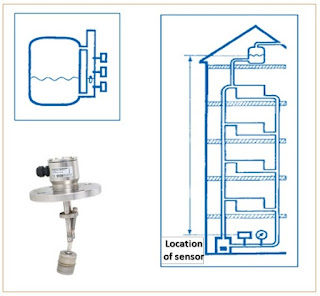

Mounting :

- The liquid-level tube and the location of the level switch are determined by the manufacturer.

- Level switches are installed at the same height as the required liquid level.

Hydrostatic level sensing:

- The measurement is based on the maximum liquid level and the location of the sensor.

Will we hope this Article is useful to you , Thank you for visiting our Blog ,

we will meet in an another good Article.

very very useful..

ReplyDeleteUseful

ReplyDelete