VFD DRIVES TROUBLESHOOTING

In this Article we are going to see VFD DRIVES TROUBLESHOOTING Common Fault Codes.

1.Drive does not start

Causes:

- Drive not ready,

- Drive not receiving a Run Signal,

- Active fault,

- DC bus too high or low,

- Run enable input not present,

Control place not correct Example trying to start from I/O

when active control place is keypad.

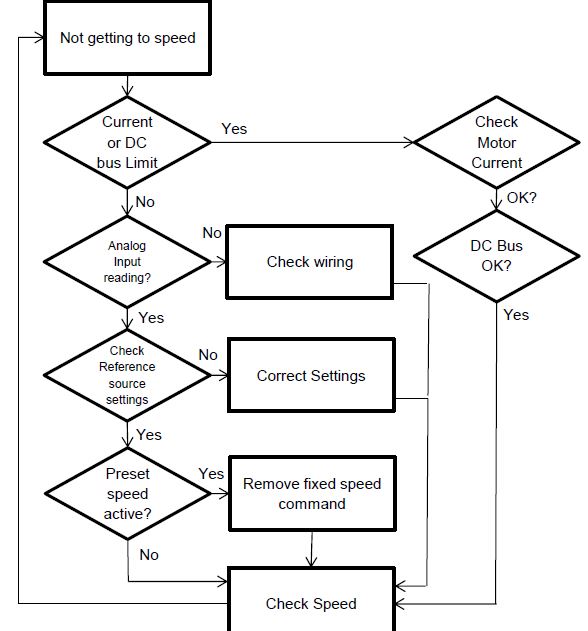

2.Drive does not get to speed

Causes:

- Missing reference,

- Preset speed or jog speed active,

Missing Reference:

- Check analog input monitor,

- Check that the drive is programmed to follow the correct input,

- Ensure the drive is not hitting any other limits,

- Check frequency reference compared to output frequency,

3.Overcurrent

Causes:

- Incorrect motor parameters,

- Mechanical fault,

- Electrical fault,

- Current measurement error,

Solution:

- Check wiring and motor for insulation failures and proper connections.

- Check for mechanical overload, Locked rotor.

- Check for proper drive size.

4.Current Limit Controller

Causes:

- Incorrect motor parameters,

- Mechanical fault,

- Electrical fault,

- Current measurement error,

Solution:

- Not all models have an indication when the current limit is reached.

- Current limit will reduce output frequency to reduce output current to at or below the current limit setting.

5.Ground Fault

Causes:

- Faulty motor,

- Electrical fault,

- Current measurement error,

- Check for loose or high resistance connections to the motor.

- Test motor for electrical failure.

- Disconnect motor leads or apply known good motor to verify current measurements.

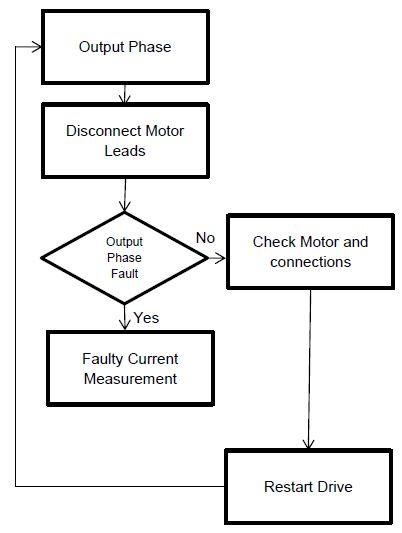

6.Output Phase Fault

Causes:

- Loose Motor Connections,

- Faulty Motor,

- Current measurement error,

- Caused by current imbalance on the output of the VFD.

- Look for loose connections or fault in motor winding's.

7.Overvoltage Fault

Causes:

- High Line Voltage,

- Regenerated voltage from load,

- Excessive line side harmonics,

- If Fault occurs during deceleration or stop command, then increase deceleration time or brake chopper may be needed.

- Cyclic loads may need regen unit or brake chopper.

- Excess harmonics may be overcharging DC link capacitors.

8.Overvoltage Controller

Causes:

- High Line Voltage,

- Regenerated voltage from load,

- Excessive line side harmonics,

- Trouble shooting is the same as for the overvoltage fault, the overvoltage controller will increase the reference in an attempt to bleed off excess voltage.

- Not all series of VFD’s have an indication of when this controller is active.

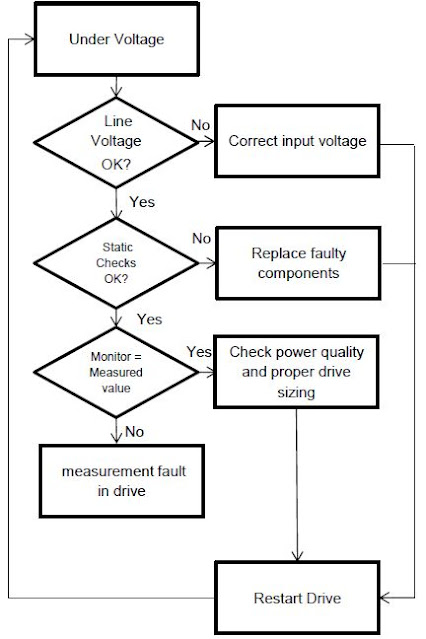

9.Undervoltage Fault

Causes:

- Low Line Voltage,

- Improperly sized drive,

Solution:

- Check for low line voltage or drops in line voltage under load.

- Check for damaged input rectifiers with static checks.

- Check for even current draw on input when drive is running.

10.Unit Over Temperature

Causes:

- High Ambient temperature,

- Insufficient airflow,

- Plugged heat sink,

- Failed cooling fan,

Solution:

- Check Main cooling fan for rotation.

- Ensure unobstructed heat sink and airflow.

- Check ambient temperature is below the drives ratings.

11.Motor Over Temperature

- Overloaded Motor,

- Operating Motor at high load at low speeds,

- Undersized Motor,

- Incorrect Motor Parameters,

- Check Motor Parameters.

- Observe current and speed.

- Current should be nearly proportional to speed, if running half speed at FLA drive will protect motor from increased thermal stress from reduced cooling.

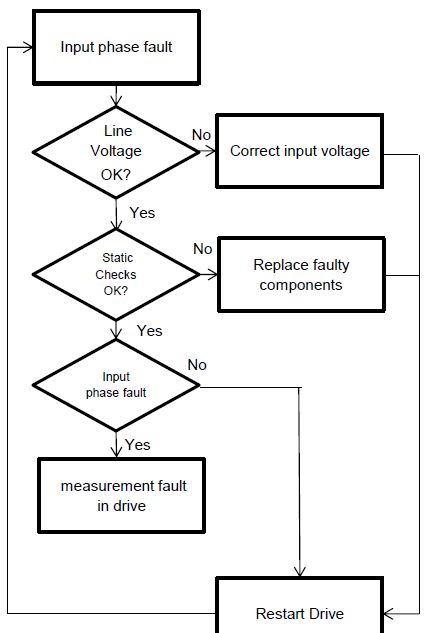

12.Input Phase Fault

Causes:

- Missing Input phase,

- Damaged Drive,

Solution:

- Check for Line Voltage imbalance.

- Check for loose connections or blown fuses.

- Check for damaged input rectifiers with static checks.

- Single phase input drives need to have this protection disabled.

- Check for even current draw on input when drive is running.

Useful

ReplyDelete