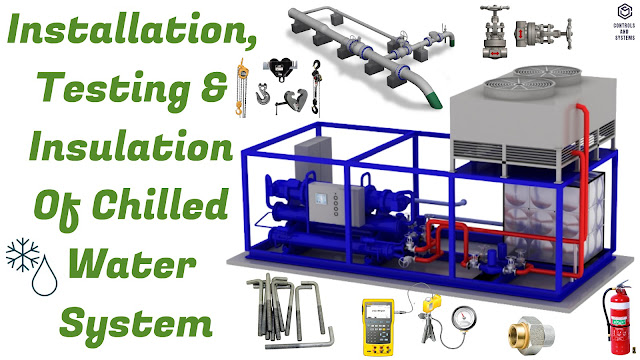

Chilled Water System Installation Methods

In this Article we are going to discuss about Installation, Testing & Insulation Of Chilled Water System.

SCOPE AND PURPOSE:

This Method Statement covers the onsite installation, testing and

insulation of the chilled water piping system including risers and the

requirements of checks to be carried out.

REFERENCE DOCUMENTS:

- Project Specifications,

- Approved shop drawings (latest revision),

- Approved material submittals,

GENERAL:

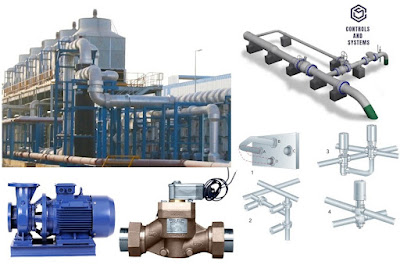

Chilled water piping system includes chilled water pipes, fittings, valves and accessories used for transport at ion (supply and return) chilled water for AHU 's and FCU's through Chilled water pumps.

Pipes and fittings up to 50 NB dia. size shall be threaded type and 65 NB and above shall be either grooved or

welded type.

EQUIPMENT:

- Electrical grinding Machine, Scaffolding, Drilling Machine, Ladders,

- Heavy duty cutter, Pipe fitter hand tools,

- Grooving machine, Electrode oven or Quivers, Threading machine, Pressure test pump,

- Welding machine, Test pressure gauges, Cutting Torch set,

RESPONSIBLE PERSONS:

- Project Engineers,

- Construction In-Charge,

- Site Engineer and Site supervisor,

- QA and QC Inspectors,

- Safety officer,

- Site Foremen,

- Pipe fitters and Welders,

- Helpers,

METHOD OF PRE INSTALLATION:

|

| Method of Pre-Installation |

- Ensure that approved material required to carry out work will be available.

- Proper materials including chilled water pipes, fittings and associated accessories are withdrawn from stores according to approved shop drawing and good engineering practices.

- Prior to commencement of work, area and access will be inspected to confirm that the site is ready to commence tile work.

- All relevant documentation and material applicable to particular section of works will be checked by site engineer before commencement.

- Physical verification of material will be carried out for any damages prior to taking from stores.

- The site engineer and supervisor will give necessary instruction to tradesman and provide necessary construction and shop drawings.

- The site engineer and supervisor will also check that tools and equipment’s available are in compliance to contract requirements.

- The site supervisor also explains tradesman regarding safety pre-cautions to be observed.

- Prior to Hydro-static Pressure testing, Site Engineer will ensure that Calibrated pressure gauges are available and are in good condition.

METHOD OF INSTALLATION:

|

| Method of Installation |

- All welding activities will be carried out by certified welders only.

- Supervisor and Foremen will carry out a site survey and mark the route of Chilled water piping as per approved shop drawings. In the event that there are any discrepancies or difficulties in executing the work, these will be brought to the notice of Project Engineer for corrective action.

- Determine the position of supports and fix the supports using anchor bolts and ensure all fixing are tight and secure.

- Any cut edges of angles, channels or threaded rods will be touch up with Zinc rich paint.

- Install the pipes in position by using suitable lifting equipment’s (If necessary),

- Assemble the pipes and fittings as per approved shop drawing.

- After installation of pipe work check for correct leveling, position alignment and proper grooving/threading or welding.

- Where the pipes of dissimilar materials are to be joined together necessary dielectric unions shall be used.

- Sufficient spacing shall be maintained between pipes for insulation.

- Spacing between supports and hangers will be maintained in accordance with latest approved shop drawings.

- Ensure all open ends of pipes, fittings and valves are covered with polyethylene sheet before leaving work space.

- All high point on piping system will be provided with an air vent. Drains will be provided at low point with an access. High point vents will be connected nearest drains.

INSTALLATION OF VALVES AND ACCESSORIES:

- Install system valves and accessories as per latest approved shop drawings.

- Ensure that system equipment, valves and accessories are secure and rigid,

- The installation shall be done allowing sufficient access to all Valves ,strainers and Gauges as per Manufacturer's recommendations.

INSTALLATION OF CHILLED WATER RISERS:

- Pipe sizes will be identified first as per latest approved shop drawing and shifted to respective floors.

- Install the supports as per approved shop drawing.

- The pipe shall be thoroughly cleaned prior to joining.

- On completion of joining, install the pipes using necessary equipment and manpower.

- After installation of risers check the pipeline for proper alignment and supports.

HYDROSTSTIC PRESSURE TESTING:

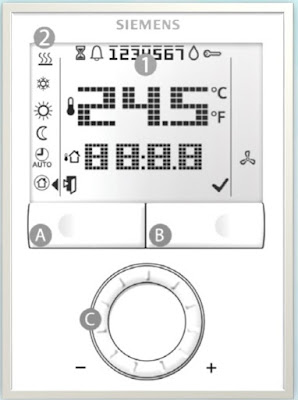

- Complete pipe work will be subjected to hydraulic pressure tested as per technical specification.

- Depending on ongoing Construction activities sectional hydro testing will be under taken to meet the requirements of the program.

- Test

pressure will not be less than 1.5 times the working pressures but not less

than 1035 kilopascal (for 24 hour period) whichever is

greater, Prior to any testing the system pressure will be detailed on the

pressure testing documentation.

- Pressure gauges used for Pressure testing will have valid calibration certificate.

- After successful Pressure testing ensure that piping system is fully drained and released for chemical cleaning which will be carried out at later date as per approved method statement

INSULATION:

- Before application of thermal insulation, Chilled water pipes will be painted with a primer paint as per specification. Painting of welded joints will be carried out after pressure testing.

- Insulation of chilled water pipe work will be carried out as per details as shown in approved submittals. Thermal insulation of welded joints will be carried out after pressure testing.

- Ensure thickness of insulation is as per approved drawing

QUALITY CONTROL

- QCE along with Project Engineer and site Supervisor will monitor that all components are installed as per the contract specifications and approved submittals.

- Inspection Request (IR) shall be submitted to the Main Contractor and Consultant during the following stages,

- After completion of installation before hydrostatic pressure test.

- Pressure testing of piping.

- After completion of insulation.

SAFETY:

- Work will commence as per safety regulations laid down in the contract specification and project safety plan.

- Proper safety harness to be used and secured, if required.

- All personal protective equipment shall be used as appropriate according to the nature of job.

- Housekeeping shall be of good standard and all cut lengths and debris shall be removed.

- Fire Extinguishers will be provided in the near vicinity during welding and cutting operations.

- Where ever required fire blanket will be provided.

- Hot work permit system will be followed.

1. HVAC ductwork methods and statements : https://youtu.be/_2o_089Vq40

2. Spiral Round Duct Installation : https://youtu.be/MJtHQQRwQUs

3. Chilled Water System Installation : https://youtu.be/ZLkj3FBZKxA

4. Fan Coil Unit Installation : https://youtu.be/QsrCFCGqTSc

5. METHOD STATEMENT FOR INSTALLATION OF FAN : https://youtu.be/g-g0DnNnTr0

6. Chilled Water Pumps Installation Methods : https://youtu.be/2BQunmmA1Nk

7. Air Handling Unit Installation : https://youtu.be/6Bl-kGMVBuM

Thank you for Visiting our Blog,

Have a great

day.

useful

ReplyDelete