Fan Coil Unit (FCU) Installation Method

In this Article we are going to see Method Statement for Installation of Fan Coil Unit.

SCOPE AND

PURPOSE:

This Method

Statement covers the on site installation of FAN COIL UNIT'S (FCU) and the

requirements of checks to be carried out.

REFERENCE

DOCUMENTS:

- Project Specifications,

- Approved shop drawings (latest revision),

- Approved material submittals,

GENERAL:

Fan Coil Units

generally be installed in locations shown in drawings, serving apartments

mechanical rooms etc, both yin concealed areas and exposed supplying cold

dehumidified air conditioned space.

EQUIPMENT:

- Drilling Machine,

- Spirit Level,

- Scaffolding,

- Hand tools of Tradesmen,

RESPONSIBLE

PERSONNEL:

- Project Engineers,

- Construction In-Charge,

- Site Engineer and Site supervisor,

- QA and QC Inspectors,

- Safety officer,

- Site Foremen,

- Pipe fitters,

- Helpers,

- Ensure that approved material required to carryout work will be available,

- Prior to commencement of work, area and access will be inspected to confirm that the site is ready to commence the work,

- All relevant documentation and material applicable to particular section of works will be checked by site engineer before commencement,

- Physical verification of material will be carried out for any damages prior to taking from stores,

- The site engineer or supervisor will give necessary instruction to tradesman and provide necessary construction and shop drawings,

- The site engineer and supervisor will also check that tools and equipment’s available are in compliance to contract requirements,

- The site supervisor also explains tradesman regarding safety precautions to be observed.

METHOD OF INSTALLATION:

- Prior to commencement of work coordinate ion will be done with other services.

- Determine the position of Fan Coil Unit on the ceiling and mark the location of supports as per approved shop drawing.

- Prepare and fix the Fan Coil Unit supports as per approved construction drawing and specification.

- Ensure that Vibration Isolators of approved make, type and model are installed.

- Install the Fan Coil Units by lifting it slowly by using suitable lifting aids (if necessary). Manufacturer's recommendations shall be followed during installation.

- Any cut edges of angles, channels or threaded rods will be touch up with Zinc rich paint.

- Fan Coil Units will be connected with Piping Connections complete with valves and accessories as indicated in approved shop drawing.

- Ensure that Dielectric unions are used for piping connection to FCU's.

- FCU Valve packages shall be provided with drain pan as shown in approved shop drawing

- Ensure that drain connections are made with adequate slope with running trap.

- Complete the duct connections to Fan Coil Units as shown in approved shop drawing.

- Complete the Electrical power connection includes earthing a all respects as per approved electrical drawing and Manufacturer's recommendations.

- Ensure that adequate space for maintenance of fan coil units and valve package is available.

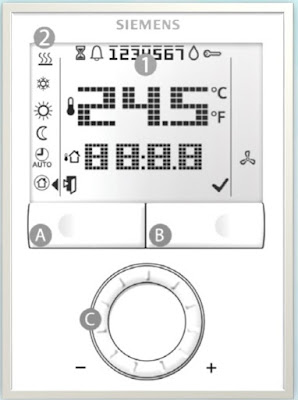

- Install the thermostat control units as per shop drawing/ Architectural PE/SS/FM drawing.

- Complete the BMS interfacing with DDC controllers as per approved BMS drawings.

QUALITY

CONTROL:

- OCE along with Project Engineer and site Supervisor will monitor that all components are installed as per the contract specifications and approved submittals.

- Inspection Request (IR) shall be submitted to the Main Contractor/Consultant.

SAFETY

- Work will commence as per safety regulations laid down in the contract specification and project safety plan.

- Proper safety harness to be used and secured, if required.

- All personal protective equipment shall be used as appropriate according to the nature of job.

- Housekeeping shall be of good standard and all cut lengths and debris shall be removed.

Post Links:

Video Links:

1. HVAC ductwork methods and statements : https://youtu.be/_2o_089Vq40

2. Spiral Round Duct Installation : https://youtu.be/MJtHQQRwQUs

3. Chilled Water System Installation : https://youtu.be/ZLkj3FBZKxA

4. Fan Coil Unit Installation : https://youtu.be/QsrCFCGqTSc

5. METHOD STATEMENT FOR INSTALLATION OF FAN : https://youtu.be/g-g0DnNnTr0

6. Chilled Water Pumps Installation Methods : https://youtu.be/2BQunmmA1Nk

7. Air Handling Unit Installation : https://youtu.be/6Bl-kGMVBuM

Thank you for Visiting our Blog,

Have a great day.

very informative....

ReplyDelete